Scratch Resistance Coating (Hard Coating)

Scratch resistance coating, or hard coating, reduces the risk of lens damage through daily wear and tear, especially under harsher environment where dust and stong wind is regularly experienced.

Sundex's super durable hard caoting, increases abrasion and scratch resistance.

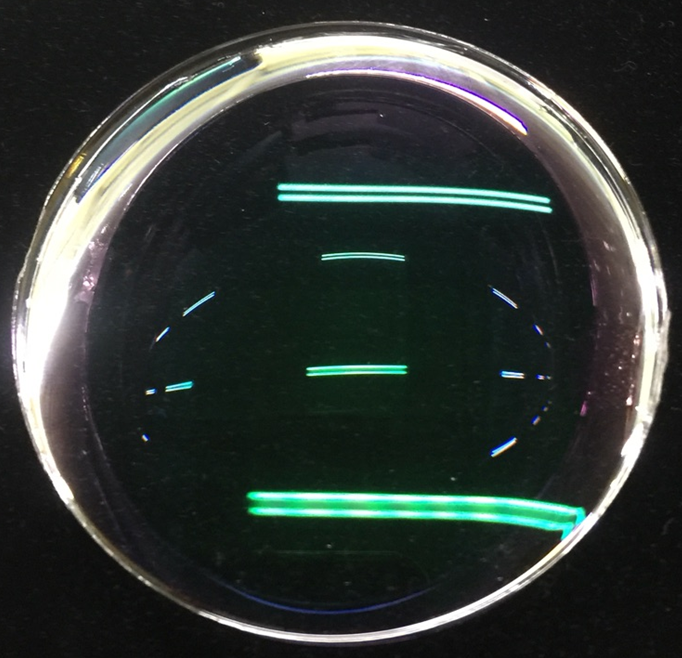

Evaporation Vacuum Coating (Hard Multi Coating)

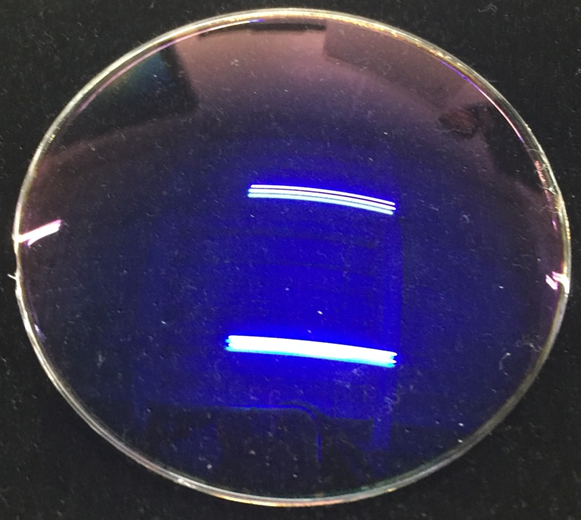

Anti-Reflective Coating

Also known as green or blue coat, it is coated using high quality eco-friendly material imported from Japan and EU.

AR coating works by utilizing the nature of chemical compounds to balance out different levels of light reflection.

Different harmful light spectrum can be filtered effectively, thus increase the wearability and excellent retina protection, the lens will provide a unified visual quality in day and night.

Multi layer coating is coated layer by layer, so the the visible color is richer, and the transmittance rate is above 98%, this also helps to prevent visual shadows and tail light reflection.

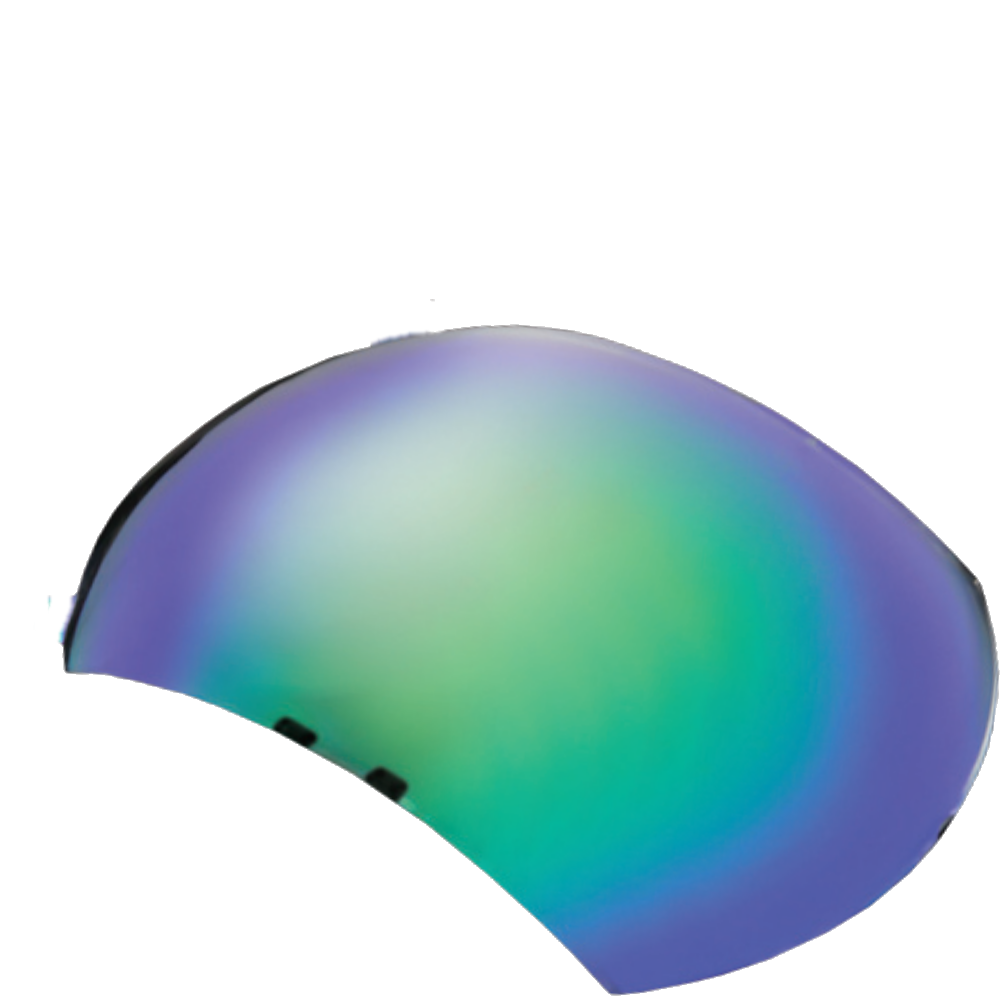

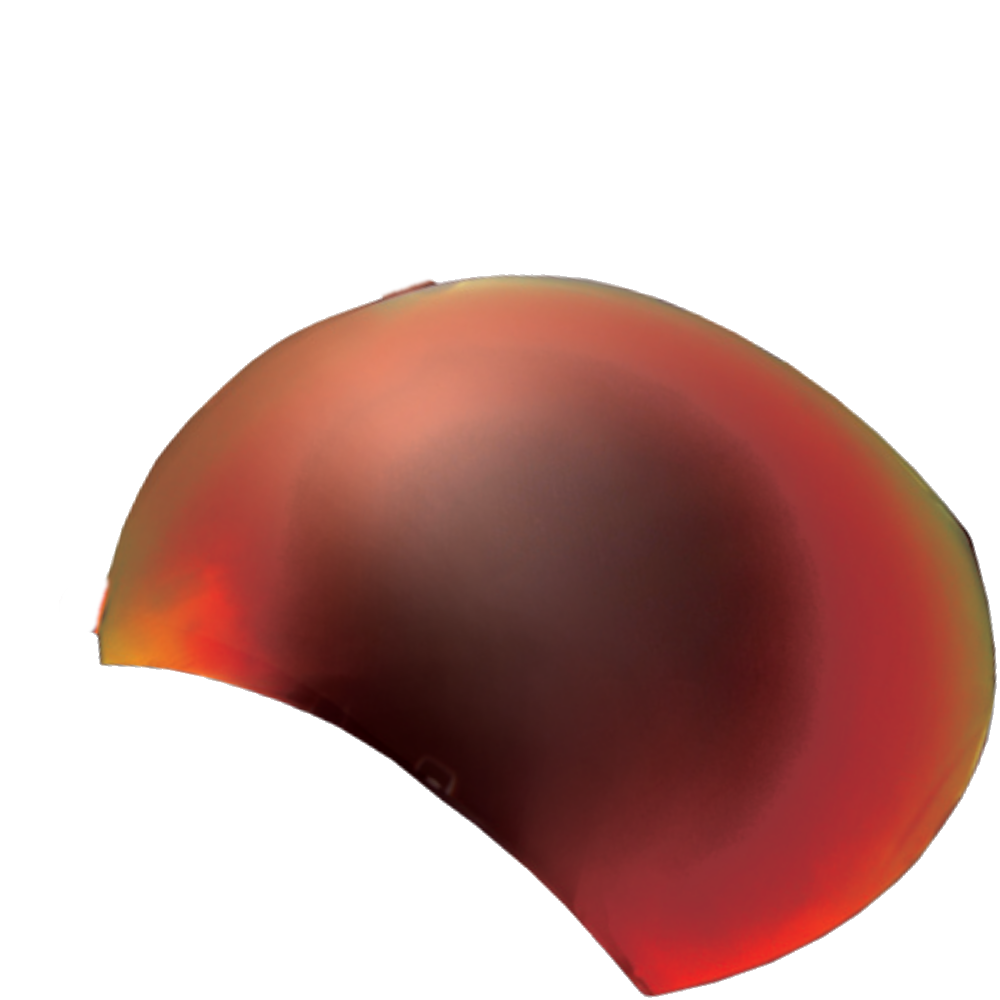

Silver Coating (Mirror Coating)

Using evaporation vacuum coating technology, materials with different spectro properties can be coated on to lens surface,

thus increasing the overall reflection rate and reduce solar glare reflected by snow and sea from non focal-direction.

Mirror coating has many different color to choose from, and so it is very fashionable.

Mirror coating have a low transmittance rate in general, so the wearer may perceive the environment to be darker than actually is.

Revo

Using evaporation vacuum coating technology, materials with different spectro properties can be coated on to lens surface,

thus increasing the overall reflection rate and reduce solar glare reflected by snow and sea from non focal-direction.

A good demonstration is by rotating the lens under a constant light source, the light reflection will be greatly diminished at certain angle.

Super Hydrophobic Coating (Nano Coating)

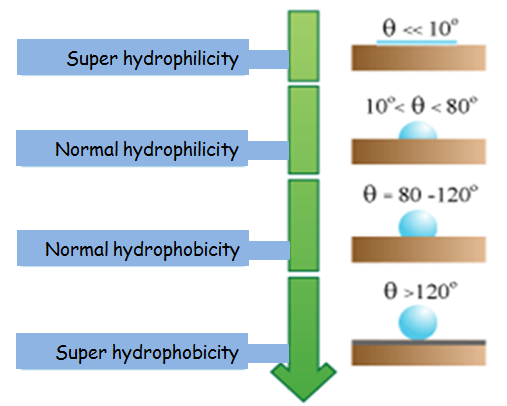

A water molecule is polar and tends to be attracted by other polar molecules, which binds together forming water droplet.

Hydrophobic molecules are neutral and non-polar, so on this type of surface, water molecule is more attract to itself.

This will a high contact angle bigger than 90 degree, in some cases this can reach upto 150 or even 180 degree.

Hydrophobic coating makes lens more durable, singer print and dust free.

.png)

.png)

.png)

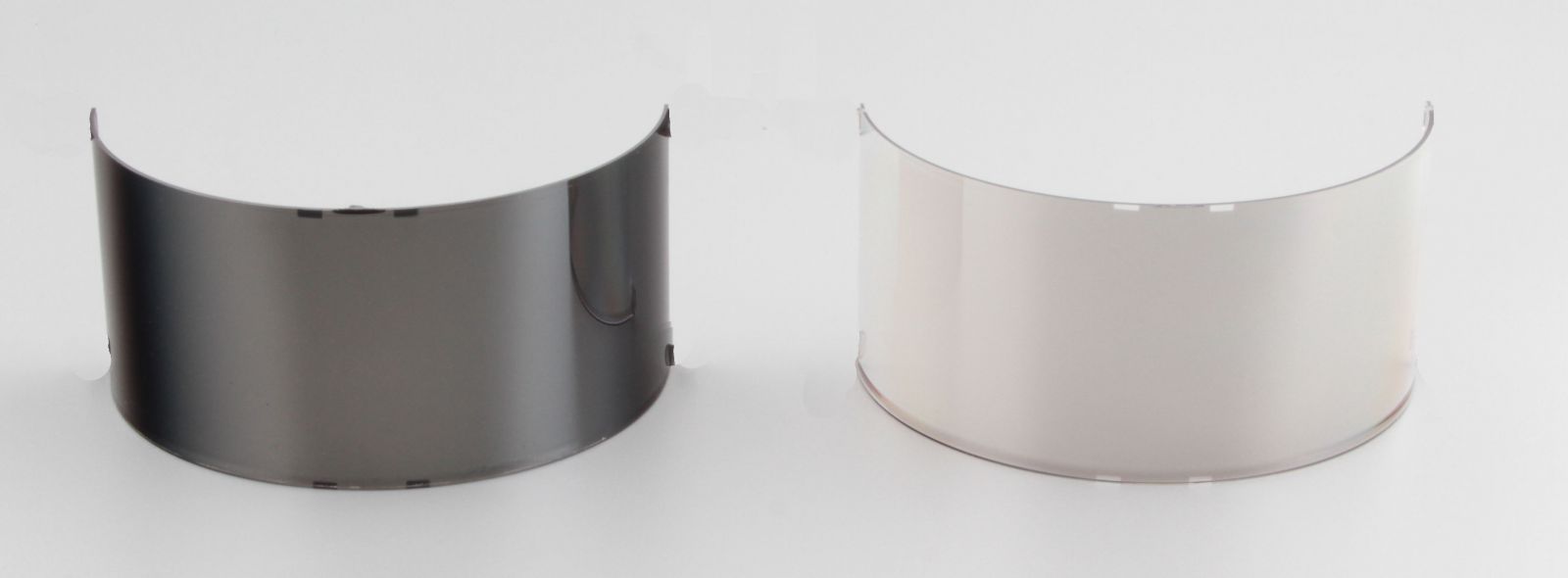

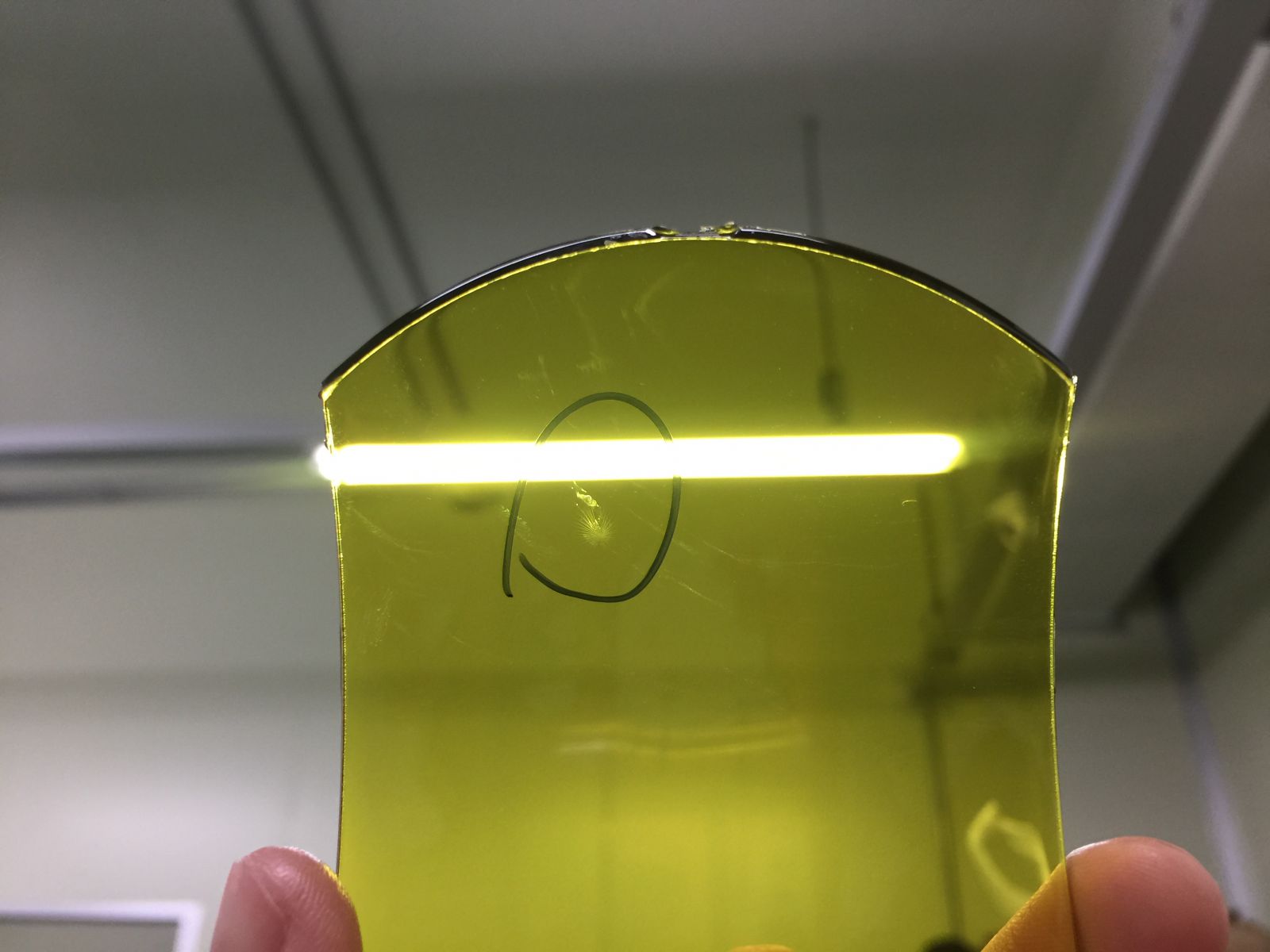

Photochromic Coating

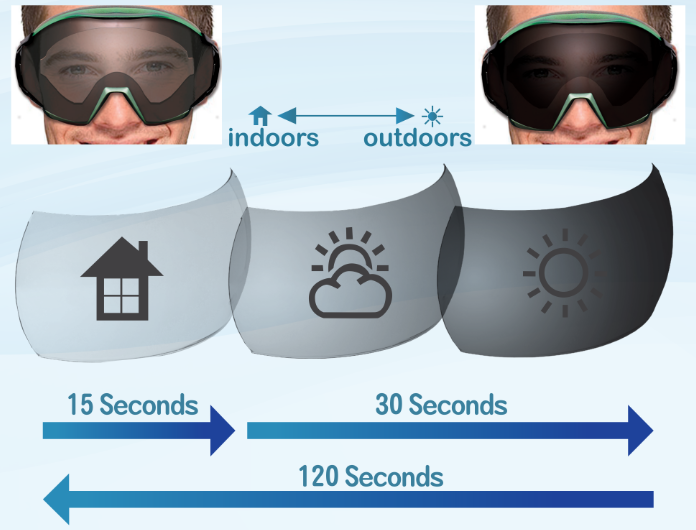

Photochromic lenses looks just like any other lenses, but the unique photochromic coating enables the lenses change color according to sunlight exposure, dark under sun light and normal when indoor.

It's secret lies in the Reduction-oxidation reaction caused by UV lights contacting silver chloride (substance vary according to lens material) and other chemicals in the coating substance.

Lens will darken according to the intensity of sun light (UV spectrum), and as this process is reversible, the lens return to normal state when the UV factor is removed (indoor).

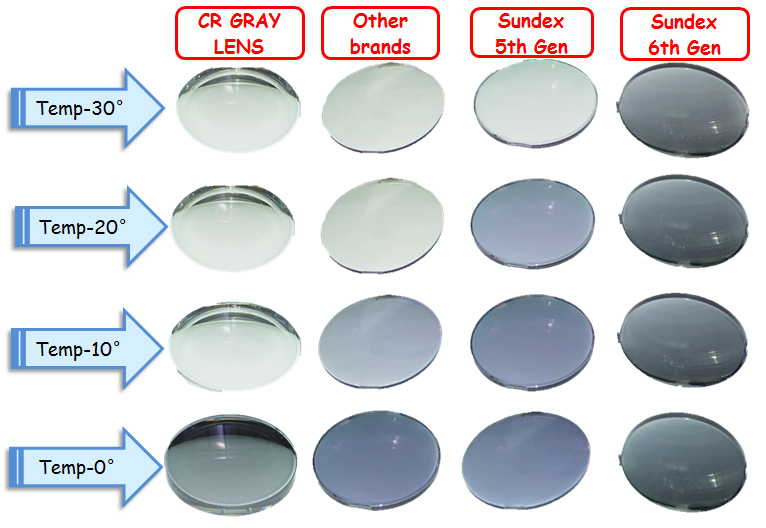

* Temperature can also affect photochromic substance, darkened state may appear to be lighter in warmer climate (tropical and sub-tropical), so photochromic lens cannot 100% replace sun lens.

* Photochromic lenses works day or night, perfect for all year round.

* Sundex Photochromic lens is great for winter sports, worry no more for the snow blind and UV light. Sundex offer you great experience with no chromatic aberration and distoration.

* Sundex Photochromic lenses reacts to UV light rapidly, the fastest on the market, we offer the clearer vision where ordinary lens cannot.

Anti-fog

Sundex anti-fog lenses eliminates the situation of seeing through thick layers of misty fog, as this is both awkward and inconvenient.

Blue Light Filter

Blue light is light source of high energy, it includes blue, indigo and purple. It passes through cornea, lens and expose on macular segment directly.

This causes damages in sensitive macualr nerve endings, Macular Leisons is the degeneration of macular area.

Blue light filter coating block out harmful blue light, 400nm to 450nm, reduce macular degeneration occurring too young.

Macular Degeneration usually occurs in elderly, however, the average occurring age is now lower due to prevelant electronic devices

.png)

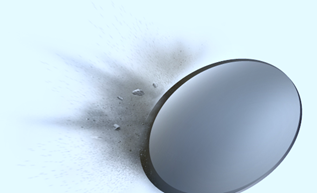

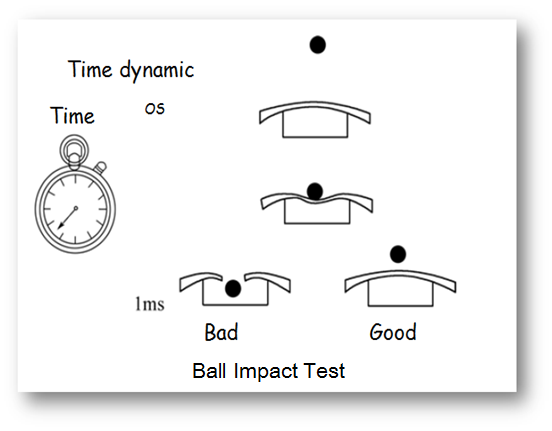

PC Lens Drop Ball Test

Drop Ball test standard was outlined by EU and USA countries to measure the impact resistance of ophthalmic lenses.

The test require a steel ball drop on to lens surface from specific height, the lens should meets standards listed below and no fracture should occur.

A. Mid level impact resistance: Lens withstand a 16 gram steel ball drop from 127cm of height.

B. High level impact resistance: Lens withstand a 44 gram steel ball drop from 130cm of height.

Safety Standards: EU and USA countries has required people involved in specifics tasks to wear safety eyewear to avoid injuires resulted in fractured lens

Normal plastic and glass lenses does not pass impact resistance listed above.

PC Lens High Velocity test

ANSI Z87.1-2003 standard: All qualified optical lens should withstand the impact of 5 gram steel ball travelling at 150 fps, and no splinter should be observed.

Before After

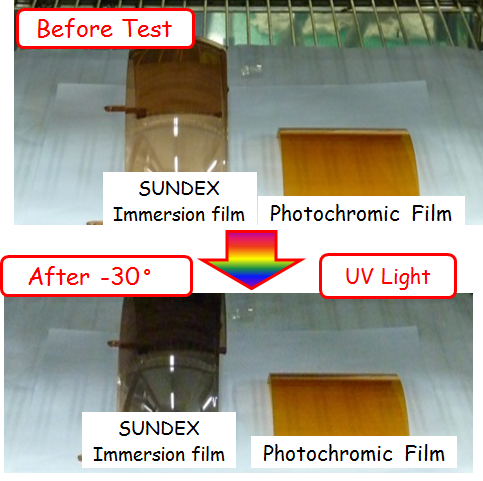

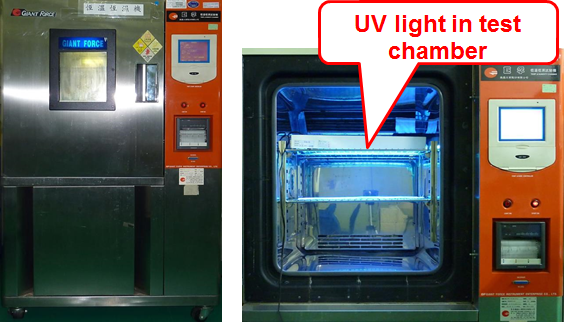

Extreme Low Temperature Test

Test Environment:-30℃

1. Place UV lamp and test subjects in the test chamber.

2. Set temperature at -30℃, moisture constant and duration at 30 minutes.

3. Turn on UV lamp for 2 minutes after the said duration.

4. Turn off UV lamp and temperature setting, take pictures.

Notes: Because of the output of UV lamp is reduced under low temperature, the exposure time has been increased.